Shipbuilding using collaborative VR grows your ROI by 90% (Part 2)

Overview

As seen in the previous post, there are many challenges around shipbuilding that needs transformation to the digital world to grow at the same pace as in other high-technology domains like aeronautical or the automotive industry. Our stakeholders in this version are the shipbuilders and operators.

Shipbuilders

Identifying Inefficient Design:

- No technology exists to highlight and showcase design flaws at an early stage. So, effective clash management remains a challenge.

- Poor presentability of data leads to flaws that remains out of sight. We can view a ship’s design only in 2D using a desktop and the mouse. Hence it becomes difficult to observe small parts using a primarily 2D device.

- There is lesser end-user involvement before construction of ship commences. Further, if the client’s approval is not taken, it can prove expensive in later stages.

Operators

Maintenance Challenges:

- Training for ship construction and subsequent maintenance is a stand-alone and non-interactive process. Training does not prove to be much useful after simply watching the design and layout in 2D screen.

- Final design data is not used for training.

- Effectiveness of training is poor due to a 2D only design layout.

What does VR do?

The following are the key achievement of using VR as an Efficiency Enabler

- 92% reduction in errors during production.

- 100% design validation between original blueprint and actual production.

- 100% user engagement in the shipbuilding process.

- 100% marketing integration.

Benefits of using Collaborative Design Review and Virtual Prototyping

- Enterprise wide gains in productivity due to seamless multi-party collaboration and interaction in real time centered on a real-scale virtual model of the ship.

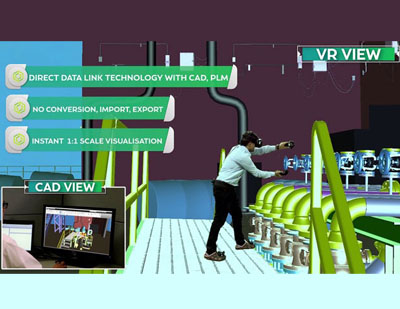

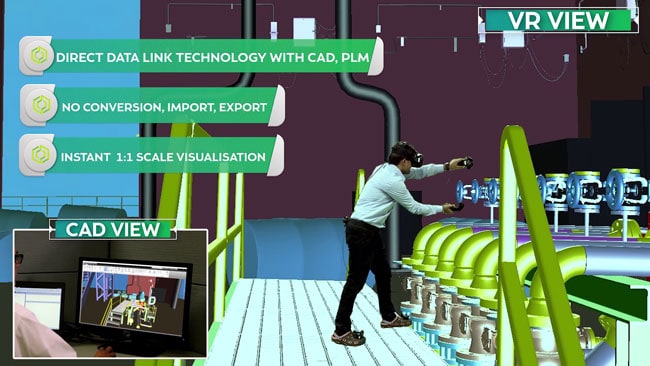

- Enables interacting with no-cost virtual prototypes of existing CAD models.

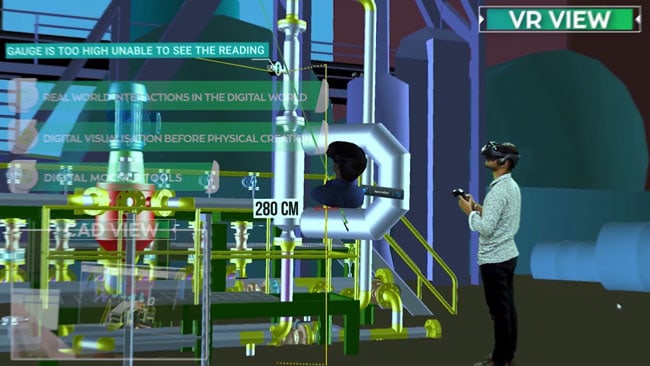

- Visualize CAD models in 1:1 scale with real time interactions like exchanging notes, measurements and annotations.

- Design Validations and feedback including reachability, ergonomics, collision and interference checks.

- Unified experience across various departments of the organizations regardless of the hardware platform with zero learning curve.

- Assured Return-on-Investment with focus on timely deliveries and zero re- construction due to design flaws.

Exxar : Transformation of 3D physical prototype to cost-free virtual prototype

Exxar offers you digital transformation and so much more. All shipbuilders can view the data in 1:1 scale in an immersive 3D environment. End user can also be invited to see the model in its real size before construction even begins. All the hardware that you need is a head mounted display, a couple of trackers and controllers and you enter the virtual world of Exxar collaborative reality. Design reviews become a lot easier with Exxar as even the minutest parts can be seen and compared to actual design. Even comments can be written in Exxar using the annotation feature.

All operations staff can experience the virtual reality environment for effective, collaborative training. Now, the training is more interactive with Exxar and meatier owing to the view in Exxar’s virtual world.