Make the construction process a smooth one by taking CAD to VR

Overview

In the Architecture, Engineering and Construction (AEC) industry, the process of designing and finalising the blueprint is quite a difficult and time-consuming task. The process of reviewing the design is also tough. As per a survey conducted by Gartner, 88% AEC companies suffer because of improper design and review at the time of commissioning. There are some important stages where designing and reviewing can be a challenge. The stages are given below :

We will consider the first 6 stages here i.e., bidding, requirement gathering, concept design architectural design. Let’s consider an example of a power plant that needs to be built. The process involved here would include contacting various stakeholders responsible for different components of the overall design like (MEP, HVAC, Structural Design and the like). Each of these stakeholders will make their designs based on the basic layout shared by the PMC (Project Management Committee). We will also see how CAD to VR transformation makes it easy.

Now let’s have an understanding on the workflows of the 3 stakeholders in this project:

MEP (Mechanical, Electrical and Piping) – Mechanical part of this is the ventilation, cooling and heat in the power plant. Electrical: Electricity and lighting are the two main areas of focus in this field. Also, they have to be careful about fire breakout in the power plant. Piping system incorporates gas, water, sewer management. Engineers ensure their proper supply and transfer through effective designs.

HVAC (Heating, ventilation, air conditioning) is the technology of indoor and vehicular environmental comfort. Its goal is to provide thermal comfort and acceptable indoor air quality.

Designer – The basic structure of the building made of iron beams is given by the designer.

The Problem – The current workflow used in the AEC Industry

Design creation

The first stage here is the design creation. The stakeholders involved normally work on different platforms for making their designs. The reviews of these designs are usually done on paper in the form of 2D drawing. The stakeholders normally have no way to collaborate with each other on the designs they have made. Also the proprietary nature of the separate platforms used makes it difficult for the model coordinator to evaluate the designs simultaneously.

Collaborative design review

1:1 scale view

The biggest reason for this is the lack of 1:1 scale visualization during the design stage making it very difficult to identify any and all clashes that might occur with multi layered assemblies. The current workflow of building incomplete physical layouts of the site for performing line inspections (mock prototypes that highlight part placement in a generalized area using chalk markings of roping off methods) making it a purely inaccurate and approximate way of validating design layouts. Keeping that in mind, one cant help but understand the reason behind the extensive delays the project faces during commissioning (almost 92%).

Furthermore, there will be no single source of truth since all are using different software / other things like paper.

The Solution – Exxar CAD to VR transformation revolutionising the Industry

View in Desktop

Navisworks to VR

VR HMD

View in Exxar (VR Environment)

Instant Collaboration, 3D design using CAD to VR software

In Exxar CAD to VR solution, the design can be viewed in one click after less than a minute. It transforms any design in the CAD software into a 3D model in immersive virtual reality environment with a background that gives it context.

Exxar CAD to VR – Design in 1:1 scale

One of the biggest advantages is that you can navigate inside the model with the added benefit of 1:1 scale visualisation, which makes the design inspection that much more accurate than the static and non-interactive view that stakeholders receive in Navisworks to VR. The design is an immersive, i.e.,you can view it in 360 degree environment.You can watch the full-model visualisation in CAD to VR as opposed to the limited physical prototyping.

Easy Navigation in CAD to VR environment

It can navigate through parts of the construction that were not possible to even be seen in other design review software. As discussed earlier in the article these physical prototypes do not cover the actual problems that come up during commissioning (mostly ergonomic related). Now with Exxar not only can we view the model in an immersive and interactive manner with navigation possible throughout the power plant.

Some more relevant features

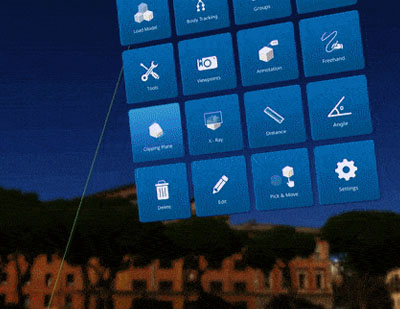

You also get access to design review features in Exxar CAD to VR like X-ray, annotation, assemble, disassemble et al. These features will first ensure that the initial design review is accurate and the time taken to review the model reduces marginally. Issues like reachability, navigational challenges for inspection and acceptability (basically all human interaction focussed problems) can now be dealt with. Apart from all these, tool handling and blindzone visualisation are also possible with Exxar CAD to VR converter software. Exxar CAD to VR transformation comes with the super speciality of giving its viewers an immersive experience with many features that make it a must buy.