Shipbuilding using collaborative VR grows your ROI by 90% (Part 1)

Overview

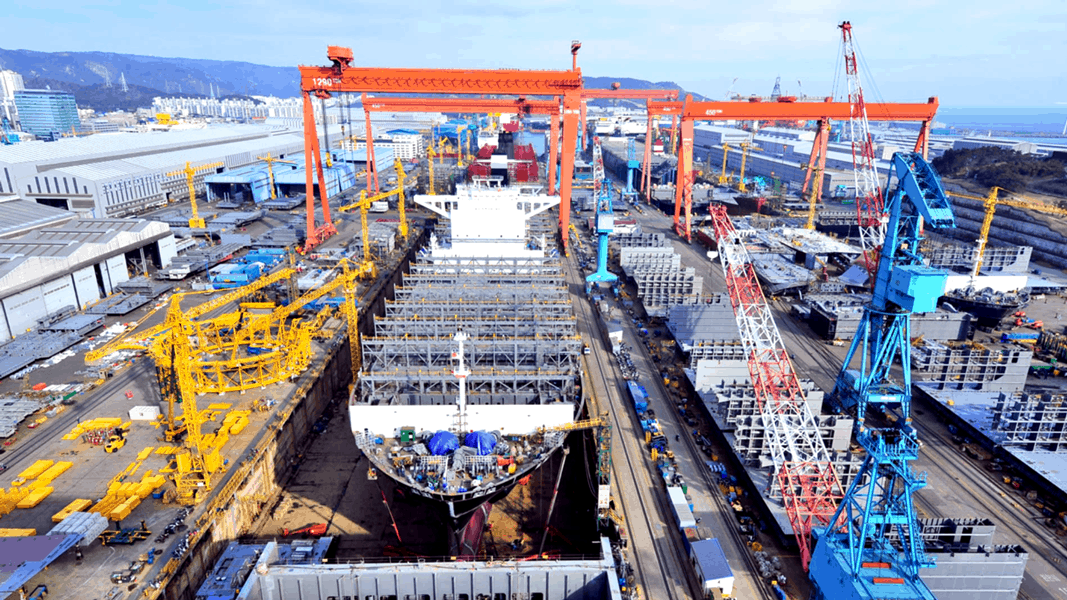

Shipbuilding is a difficult task. It is a complicated compound of art and science and both ship design and construction are multidisciplinary activities.

It is a universally accepted fact that shipbuilding acts as a catalyst for overall industrial growth due to spin off to other industries, including steel, engineering equipment, ports, infrastructure, and ultimately trade. The direct potential of the shipbuilding industry in contribution to GDP is therefore tremendous.

- Ship owners

- Ship builders

- Operators

- Suppliers

Challenges

One of the biggest issues that the industry faces is the value, or lack thereof, placed on building a virtual model prior to construction. This is largely due to the tradition that the first major milestone payment is tied to laying down tangible deliverables and not a digital virtual prototype.

Challenges faced by the ship owners

The design is usually in the form of 2D drawings. So, many details are skipped or not clearly visible.

They pay for the planning and construction work, so the costs increase by 52% because they have to rebuild parts that cause clashes and collisions. Furthermore, travel costs of each stakeholder for the planning and design review meetings have to be paid from the owner’s pocket.

Challenges faced by suppliers

Empirical evidence shows that the lack of integration and coordination between partners of the same supply chain affects the quality and the delivery date.

Solution

Digital transformation can change the whole process and make it more efficient. The shipowners can connect with other stakeholders and zero in on designs, materials and so on.

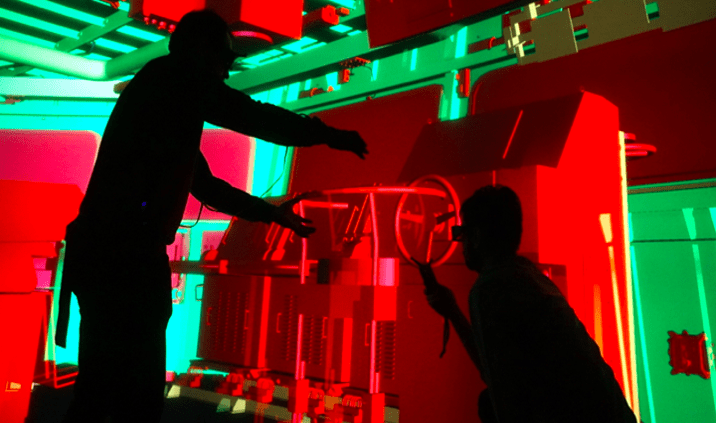

The clashes, collisions and interferences can be dealt with in the design review phase itself and there is no need for clash management in the later stages (during construction). Used by workers without giving them any discomfort.They can also check through ergonomic analysis, if the parts can be fixed.

In case of suppliers, they can view the 3D data in an immersive environment with the option of assembling and disassembling parts for which they are sending the material and check if the measurements of the components are precise. They will get clarity as to what they have to send to make these parts.

They can see it in 1:1 scale, i.e., in its actual size. Natural interaction is possible in Exxar and you can check if any parts are going to affect the postures of your staff (a process known as ergonomic analysis).

Exxar – Collaborative VR as a Saviour for Shipbuilding

Exxar is the flagship product of VizExperts. It not only transforms your design review challenges but does it in the most economical way. The best part is that the model can be viewed in VR in less than a minute and just one click.

There is no need to build a 3D prototype of the ship in the real world. You have to just use Exxar to take your data from CAD design software and then do as many iterations as you can, on the same virtual model.

You get to see your ship in 1:1 view in the virtual world with the options of commenting, collaboration of different stakeholders from different geographical locations. Instead of 2D drawing, we are using 3D models in an immersive environment for a clearer picture.

Clash and collision can be prevented by reviewing design model in Exxar. Ergonomic analysis can be done. Infact, there is a human module in Exxar, so the staff’s welfare is also the platform’s responsibility. Rework can be removed by 99.90 %.